Precision Sealless Pumps Pvt. Ltd. is a leading provider of innovative and reliable pumping solutions.

Precision Sealless Pumps Pvt. Ltd. is a leading provider of innovative and reliable pumping solutions.

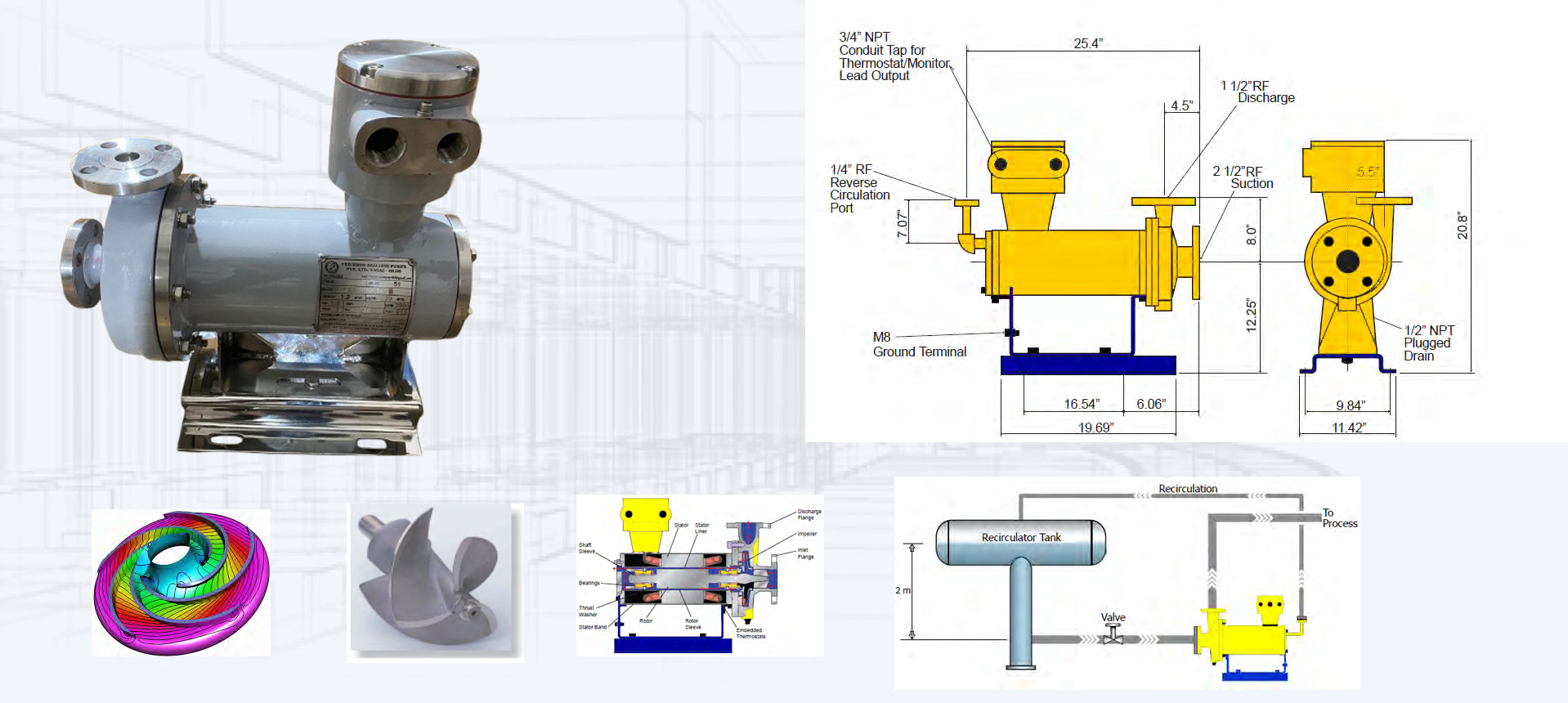

Ammonia Pupm

The Pump have few spares i.e. one set of self lubricated Carbon Bush Bearing, Bearing Sleeve , Thrust Washer & Gasket & O-ring Sets, these Spares are recommended to stock for all clients for fields replacement and for smooth running of pumps for years.

The demand of liquid Ammonia Pumps are increasing day by day in different segments of refrigeration Industries and this is because of its unique advantages and benefits with the overfeed system. Liquid Ammonia pump is the heart of the Overfeed system which pumps the liquid ammonia throughout the refrigeration system and it is important that it should run without any leakage and Trouble free operation for years.

PRECISION Offers you the best liquid ammonia pumps with sealless canned motor technology with high efficiency and quality, outstanding durability ,reliability , inexpensive operation and ready stock availability.

| PUMP MODEL | FLOW (m /hr) | HEAD (m) | MOTOR POWER (KW) | RATED CURRENT (AMP.) | SUCTION | DISCHARGE | WEIGHT (K.G) |

|---|---|---|---|---|---|---|---|

| RC 32-160/1.5 | 5.0 | 25 | 1.5 (2 HP) | 4.8 | 50 (2") | 32 (1.25") | 75 |

| RC 32-160/2.2 | 8.0 | 35 | 2.2 (3 HP) | 6.3 | 50(2") | 32 (1.25") | 90 |

| RC 40-200/2.6 | 10 | 45 | 2.6 (3.5 HP) | 6.8 | 65 (2.5") | 40 (1.5") | 95 |

| RC 40-200/3.7 | 15 | 50 | 3.7 (5 HP) | 9.0 | 65 (2.5") | 40 (1.5") | 100 |

| RC 40-200/5.5 | 20 | 55 | 5.5 (7.5 HP) | 12.5 | 65 (2.5") | 40 (1.5") | 110 |

| RC 40-200/7.5 | 25 | 75 | 7.5 (10 HP) | 15.2 | 65 (2.5") | 40 (1.5") | 120 |

| CASING | SG IRON / C.I / CF8 |

| IMPELLER | SG IRON / WCB / CF8 |

| BEARING | CARBON GRAPHITE |

| BEARING SLEEVE | SS316 + HCR |

| THRUST WASHER | SS316 + HCR |

| STATOR CAN | SS316L |

| GASKET / O-RINGS | CFT/PTFE |

| FLANGES | ANSI B16.5 150# |

| SHAFT | SS410 / SS304 |