Our Brochures

Download

Precision Sealless Pumps Pvt. Ltd. is a leading provider of innovative and reliable pumping solutions.

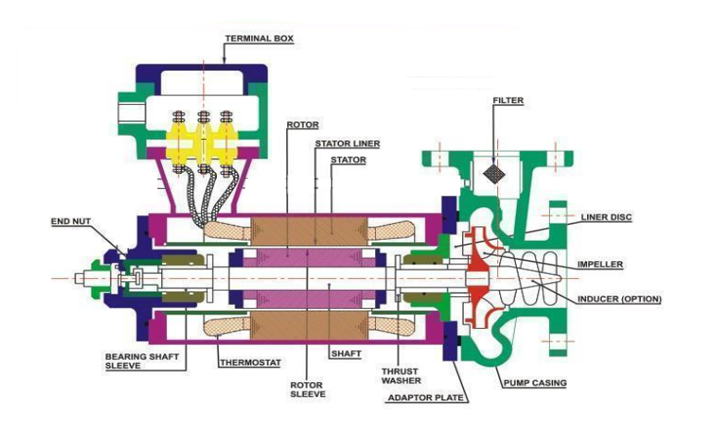

Precision Canned Motor Pumps are developed, based on the technical know-how from Nikkiso Co.Ltd., Japan. Canned Motor Pump is a centrifugal pump with pump and hermetically sealed electric motor mounted on single shaft thus eliminating the requirement of mechanical seal or other sealing device. Entire rotating assembly is immersed in the liquid, and motor stator and rotor are isolated from the pumped liquid with corrosion resistant, non-magnetic liner and sleeve. A part of the pumped liquid is bypassed through the motor, for cooling of motor and lubricating the bearing.

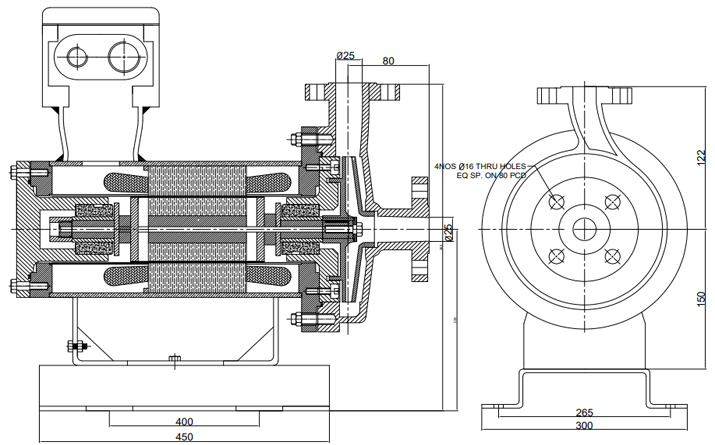

Axial suction and top centre line delivery. Smooth hydraulic passages for high efficiency. Volute type casing connected to liner disc and adapter plate.

Enclosed/ semi-open type, statically and dynamically balanced. Hydraulic balancing of impeller achieved by means of automatic thrust balance arrangement.

Auxiliary impeller for bearing lubrication and motor cooling is also available.

Stainless steel shaft accurately machined and ground. It is supported by ceramic / carbon graphite sleeve bearings in motor which are lubricated by pumped liquid. A return passage for circulating liquid for cooling motor and bearing lubrication available through the shaft.

Clockwise viewed from driving end.

2/4 pole, 3 phase, 415V, 50 Hz, Class of insulation F, H or C. Flame-proof and explosion proof construction with built-in safety devices available.

Standard : Drilled toANSI-B 16.5 Class 300.

Optional : Drilled to DIN/IS/ASA/BS.

Dry run protection device, single phase protection, over current and under current protection devices Winding temperature detector (ResistanceTemperature Detector andThermistor).

Bearing wear monitor Mechanical andElectrical.

Direction of rotation detector.

In today’s industries, where safety, efficiency, and reliability are paramount, Canned Motor Pumps have emerged as a game-changer. At Precision Sealless Pump, we are proud to be a leading manufacturer, supplier, and exporter of Canned Motor Pumps, delivering cutting-edge pumping solutions for critical and hazardous applications across the globe.

A Canned Motor Pumps is a sealless centrifugal pump where the motor and pump are integrated into a single hermetically sealed unit. This design eliminates the need for mechanical seals, which are typically the weakest point in conventional pumps, especially when handling toxic, corrosive, or volatile fluids.

Our Canned Motor Pumps are engineered to perform in some of the most demanding industries, including:

As a trusted manufacturer and exporter of Canned Motor Pumps, we at Precision Sealless Pump focus on delivering top-tier products that meet international safety and performance standards. Our engineering team provides customized pumping solutions tailored to your exact fluid handling needs.

Whether you need a standard Canned Motor Pump or a fully customized system, Precision Sealless Pump is your reliable partner for high-performance, maintenance-free pumping technology.

We are one of the best Canned Motor Pump manufacturer, Canned Motor Pump Exporter, Canned Motor Pump supplier in India. Please contact order here.

The stator is canned is canned in the air gap, confining the liquid in the rotor chamber. The pump liquid circulates through the rotor chamber, cooling the motor, and lubricating the slide bearing that support the rotor. The casting of the chamber forms a seal less enclosure that confines the liquid without any precision sealing.

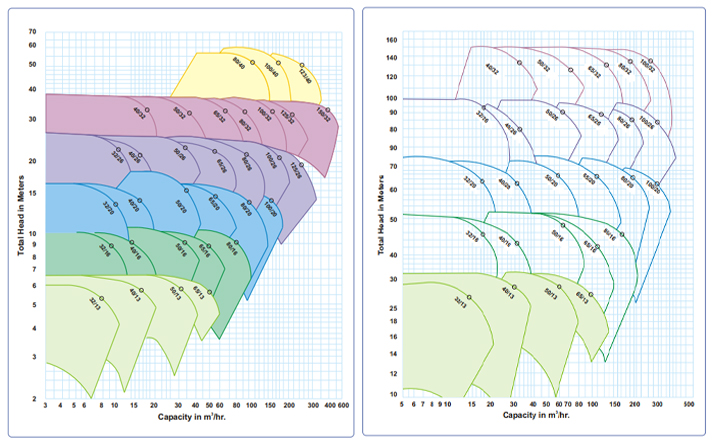

| Delivery size | up to 250 mm |

| Capacity | up to 1000m3 / hr |

| Head | up to 135 m0.95 |

| Temperature | - 40o C to +270o C |

| Working Pressure | upto 120 Kg/cm |

| Speed | 3000 RPM (Syn) 1500 RPM (Syn) |

| Voltage | 415V, 50 Hz 3 Phase |