High Temperature Canned Motor Pump

High Temperature Canned Motor Pump - Precision Engineered for Demanding Applications

Manufacturer, Supplier & Exporter - PRECISION SEALLESS PUMP

In industries where extreme temperatures meet hazardous or sensitive fluids, reliability and safety aren’t optional—they're critical. That’s where High Temperature Canned Motor Pumps by PRECISION SEALLESS PUMP come in. As a trusted manufacturer, supplier, and exporter, we deliver robust solutions designed to thrive under the harshest thermal conditions while maintaining zero leakage operation.

What is a High Temperature Canned Motor Pump?

A canned motor pump integrates the motor and pump into a single, hermetically sealed unit, eliminating dynamic seals and the risk of leakage. When designed for high temperature applications, these pumps are engineered with materials, insulation systems, and thermal barriers capable of withstanding elevated fluid and ambient temperatures—often up to 350°C or higher.

Key Features of Our High Temperature Canned Motor Pumps:

- Sealless Design : No mechanical seals, which means zero leakage and zero emissions

- Thermal Stability : High-grade insulation materials and cooling options for sustained operation at elevated temperatures

- Corrosion & Wear Resistance : Suitable for aggressive chemicals, hot oils, heat transfer fluids, and hydrocarbons

- Quiet Operation : Low noise and vibration with fully enclosed construction

- Compact & Safe : Space-saving design with intrinsically safe operation—ideal for explosive and flammable media

Applications Across Diverse Industries :

- Petrochemical Plants

- Thermal Oil Circulation

- Chemical Processing Units

- Pharmaceutical Manufacturing

- Heat Exchanger Systems

- Reactor Feed & Circulation

- Renewable Energy & Solar Thermal Systems

Wherever high-temperature fluid handling is essential, our pumps deliver unmatched performance with precision and protection.

Why Choose PRECISION SEALLESS PUMP?

As a leading manufacturer, supplier, and exporter of High Temperature Canned Motor Pumps, we offer:

- Custom Engineered Solutions

- Strict Quality Control & International Standards

- Global Export Capability

- Expert Technical Support & After-Sales Service

- Compliance with ATEX, API, and ISO Certifications

TECHNICAL RANGE :

| Delivery Size |

up to 250 mm |

| Capacity |

up to 1000 m³/hr |

| Head |

up to 135 m |

| Temperature |

-40°C to +270°C |

| Working Pressure |

up to 120 Kg/cm² |

| Speed |

1500 / 3000 RPM (Synchronous) |

| Voltage |

415V, 50 Hz, 3 Phase |

SPECIAL FEATURES :

- No seal - No leakage

- No coupling - No alignment and no vibration problem

- No separate lubrication of bearing - No contamination of lubricant

- No antifriction bearings

- Small and compact design - Space-saving installation

- Easy maintenance and longer life

- Extremely low noise level

- Absolute safety from risks of fire, explosion and leakage

- Automatic thrust balancing

- Vacuum-tight construction - Prevents air contamination of process liquid

SPECIAL FEATURES :

High temperature canned motor pumps are ideal for pumping:

- Toxic and hazardous liquids

- High temperature and high pressure services

- Nuclear power plants

- Lithium Bromide circulation in refrigeration plants

- Ammonia transfer in fertilizer plants

- Refineries, chemical and pharmaceutical industries

- Other process industries handling toxic, hazardous, or expensive fluids

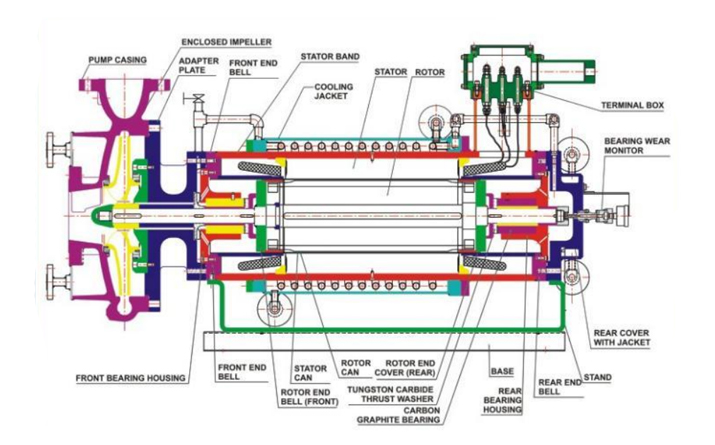

CONSTRUCTIONAL FEATURES :

- Based on Nikkiso Co. Ltd., Japan technology

- Pump and motor mounted on single shaft - no mechanical seal required

- Entire rotating assembly immersed in liquid

- Stator and rotor isolated by non-magnetic, corrosion-resistant liner

- By-pass of pumped liquid through motor for cooling and lubrication

- Axial suction and top centerline delivery

- Volute type casing with liner disc and adapter plate

- Enclosed/semi-open impeller - statically and dynamically balanced

- Automatic thrust balance arrangement

- Auxiliary impeller for bearing lubrication and motor cooling

CONSTRUCTIONAL FEATURES :

- Casing : Stainless Steel CF8M / CF3M

- Impeller / Auxiliary Impeller : Stainless Steel CF8M / CF3M

- Stator Liner : Hastelloy / Inconel / SS316L

- Rotor Sleeve : Hastelloy / Inconel / SS316L

- Bearing : Ceramic / Carbon Graphite

- Thrust Washer : Tungsten Carbide / SS316L with HCR/ CeramicCoating

- Shaft Sleeve : Tungsten Carbide / SS316L with HCR/ CeramicCoating

ELECTRICAL AND SAFETY FEATURES :

- 2/4 pole, 3 Phase, 415V, 50Hz Motor

- Class of insulation: F, H, or C

- Flame-proof and explosion-proof construction available

- Built-in protection devices :

- Dry run protection

- Single phase protection

- Over current / under current protection

- Winding temperature detector (RTD / Thermistor)

- Bearing wear monitor (Mechanical & Electrical)

- Direction of rotation detector

With years of expertise and a deep commitment to innovation, PRECISION SEALLESS PUMP has become a preferred partner for industries worldwide looking for safe, leak-free, and high-performance pumping systems.

Contact Us Today to learn more about our High Temperature Canned Motor Pumps or to discuss your specific process needs.

We are High Temperature Canned Motor Pumps manufacturer, High Temperature Canned Motor Pumps exporter, High Temperature Canned Motor Pumps supplier in India.

High-Temperature Canned Motor Pumps are specialized pumps designed to handle fluids at elevated temperatures while maintaining safety, efficiency, and durability. These pumps are ideal for industries requiring the transfer of hot liquids, such as chemicals, oils, or heat transfer fluids.