Our Brochures

Download

Precision Sealless Pumps Pvt. Ltd. is a leading provider of innovative and reliable pumping solutions.

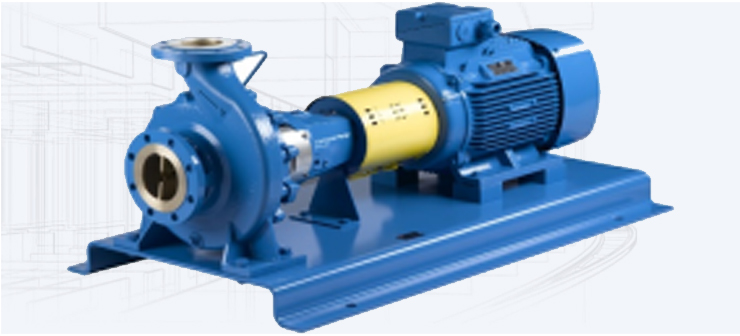

Looking for a trusted centrifugal pump manufacturer and supplier for your industrial fluid handling needs? PRECISION SEALLESS PUMP is a name you can count on. As a leading manufacturer, supplier, and exporter of centrifugal pumps, we specialize in delivering high-performance, sealless, and leak-free pumping solutions for a wide range of industries.

A centrifugal pump is a mechanical device designed to move fluid by the transfer of rotational energy from one or more driven rotors (called impellers). These pumps are widely used due to their simple design, smooth flow output, high efficiency, and low maintenance needs.

At PRECISION SEALLESS PUMP, we manufacture robust and reliable centrifugal pumps that are ideal for chemical processing, pharmaceuticals, petrochemicals, water treatment, food & beverage, and other critical industries. Our designs are leak-proof, corrosion-resistant, and engineered for safe handling of hazardous, corrosive, and toxic liquids.

As a reputed centrifugal pump exporter, we supply our world-class pumps to clients across Asia, Middle East, Africa, Europe, and the Americas. With a strong focus on quality, reliability, and performance, our products meet international standards and are trusted by industries worldwide.

We offer full customization support to match your application needs. Our dedicated technical support team ensures timely assistance, spare part availability, and long-lasting customer relationships.

We, PRECISION SEALLESS PUMP is one of the best centrifugal pump manufacturer, centrifugal pump exporter and centrifugal pump supplier in India. Please call to enquiry now.

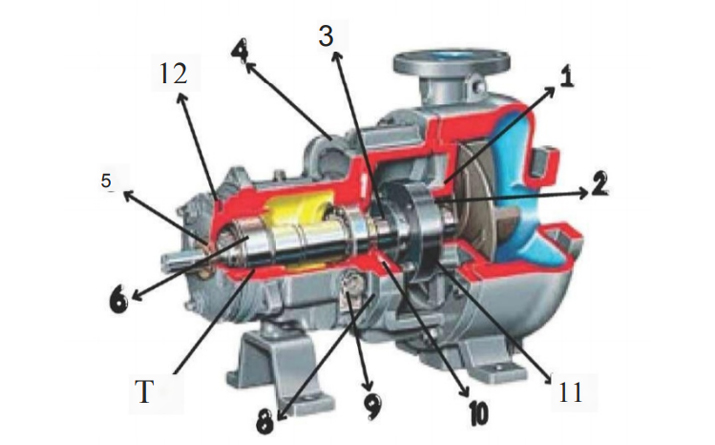

A centrifugal pump is a mechanical device designed to move a fluid by means of the transfer of rotational energy from one or more driven rotors, called impellers. Fluid enters the rapidly rotating impeller along its circumference through the impeller’s vane tips. Our centrifugal pumps are engineered efficiency and durability . Centrifugal pumps are one of the most common types of pumps used in various industries. They operate by converting rotational kinetic energy into fluid energy.

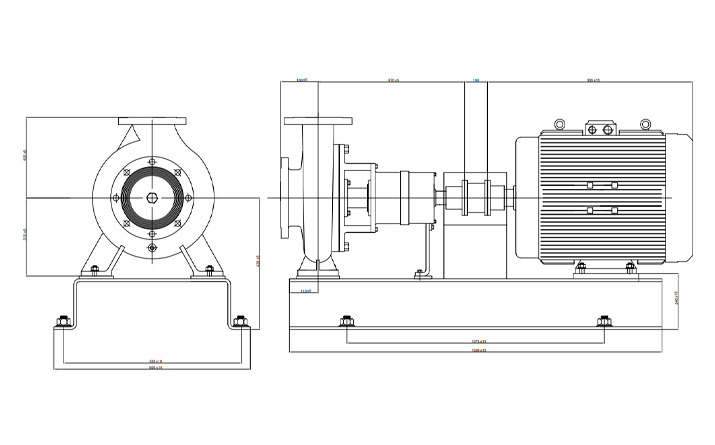

| Delivery Size | up to 200 mm |

| Capacity | up to 800 m³/hr |

| Total Head | up to 150 meters |

| Operating Temperature | -30°C to +180°C |

| Working Pressure | up to 25 Kg/cm² |

| Speed | 1450 / 2900 RPM |

| Power Supply | 415V, 50Hz, 3 Phase AC |

| Component | Available Materials |

|---|---|

| Casing / Cover | CI, SS304, SS316, SS316L, Alloy 20, CD4MCu |

| Impeller | CI, SS304, SS316, Bronze, Alloy 20, Teflon coated |

| Shaft Sleeve | SS410, SS316, Ceramic Coated |

| Seal Options | Single / Double / Cartridge Mechanical Seals |

| Bearings | Antifriction, Deep Groove / Angular Contact |